We manufacture a wide range of steel wires from 0.8 to 5.00 mm, as per BS EN 10244-2/2001, 10257-1/98 or to fit your specific requirements.

Steel Applications

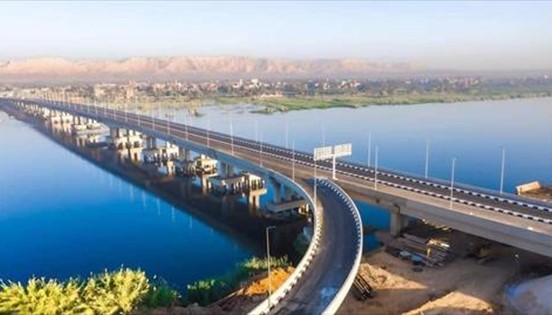

Since 2006, Elsewedy Electric Steel Applications has provided a wide range of reinforcement solutions to the Egyptian market. Our product line complies with international standards and offers galvanized steel wires, pre-stressed concrete strands and pre-stressed concrete wires and bead wire. Currently, we trade and export to more than 26 nations worldwide.

Elsewedy Electric Steel Applications follows explicit quality control procedures of inspection, starting from raw material to manufacturing and packaging processes, through a series of high technology on-line instruments, followed by laboratory tests, such as geometrical, zinc and electrical tests, and abiding to the international standards. With a 90,000 m2 production facility and fully automated control systems utilizing cutting edge technology, we offer our customers the most effective and efficient solutions.