Iskraemeco building a smart factory to optimize processes and productivity

September 2021

Implementing a smart factory concept in Iskraemeco requires a step-by-step methodological approach to make the best decisions. The main idea is to use artificial intelligence to improve the physical manufacturing process. It helps us to learn, adapt, and meet customer and market needs but also to improve cost efficiency, thus guaranteeing high quality products.

Introducing the lean concept and ensuring information transparency is one of the most important steps. The benefits of such an approach are identifying weaknesses and taking immediate action to eliminate them, as well as reducing inventories and lead times and increasing productivity.

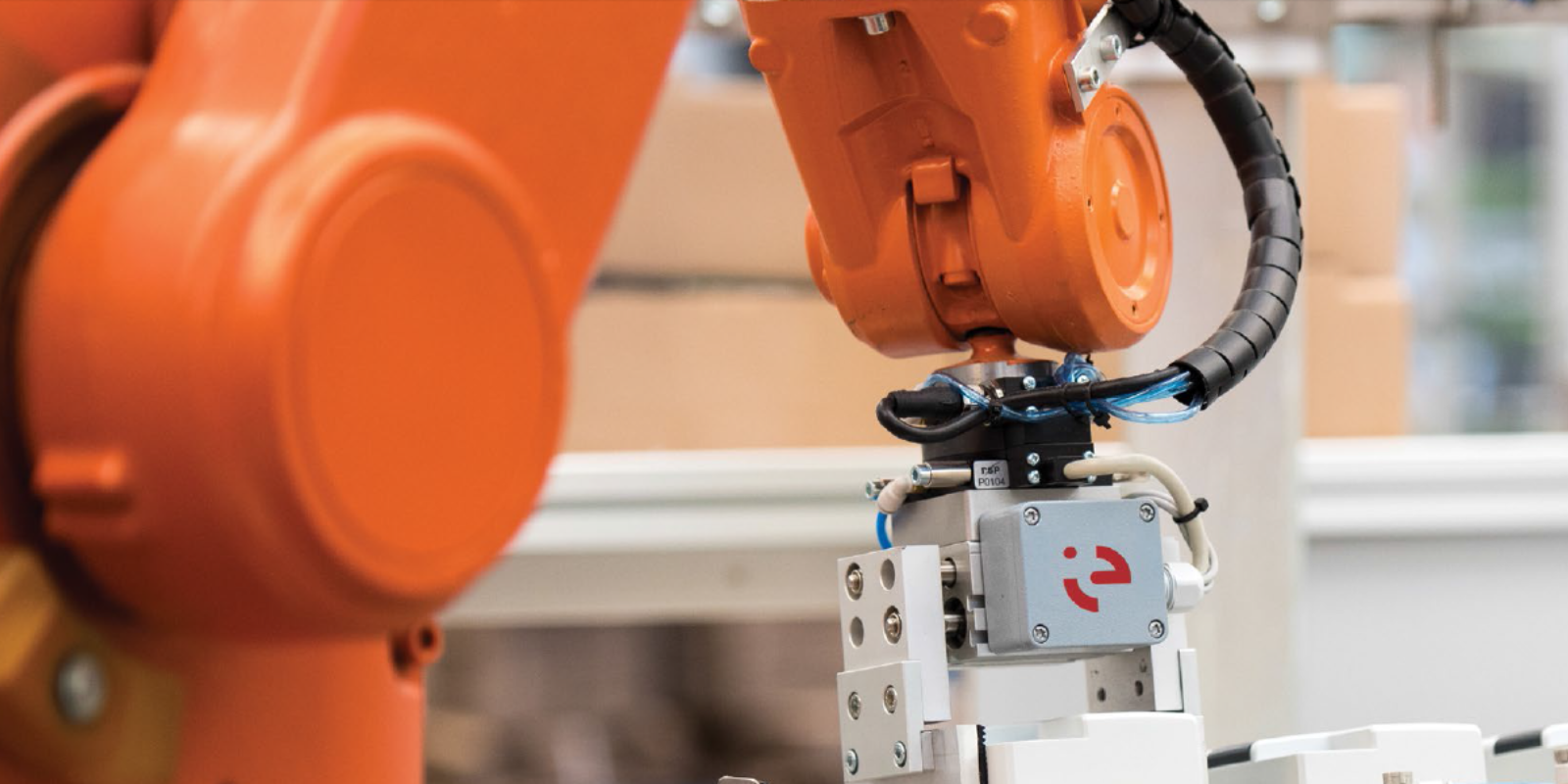

The main benefits of investing in a smart factory are also safer, more efficient, and reliable processes. Automation of production and logistics enables us to improve quality of our products and further ensure workplace safety.

The use of artificial intelligence in the factory creates a dynamic production environment, that gives us the desired results - reducing costs while improving quality and reliability. To establish simulation and modeling, we plan to introduce digital twins and automated production planning which will provide ROI and increase machine utilization.

In today’s business environment, data exchange is at the heart of any smart factory concept, including ours. The structure of Iskraemeco’s smart factory today consist of a combination of production, information, and communication technologies, as well as an integration across the production supply chain connected through an IoT platform. The IoT platform also enables the connection of machines, sensors, devices, and employees across the entire production process. The biggest advantage is ensuring data credibility, real-time data and to enabling predictive maintenance.

As Iskraemeco’s smart factory evolves, so do the roles that employees take on. Through the pre-qualification process and training, people are slowly taking on more complex roles.